DESCRIPTION

It is used for pumping the following:

- light (gasoline, diesel fuel) and dark (oils, fuel oil residue) oil products,

- viscous mud oil residue from tanks, cisterns, tankers, storages.

Main advantages:

- pumping of high viscous fluids up to 500 centistoke and high gas content fluids. Till the present day, it was possible only with the use of piston pumps.

- pumping of fluids with high content of large hard particles (up to 20 mm).

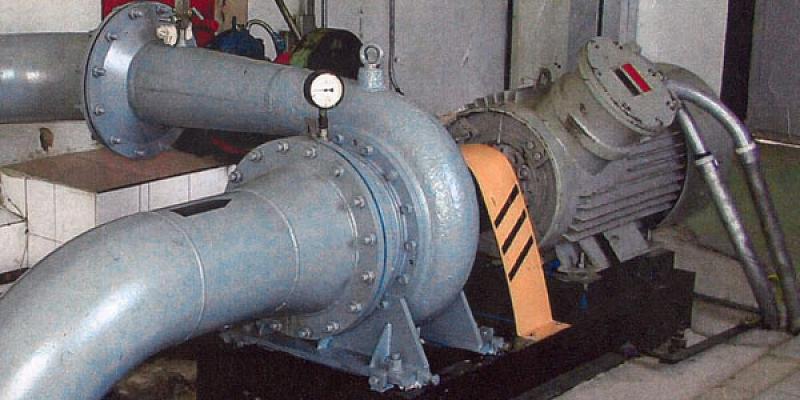

TECHNICAL SPECIFICATION

-

Suction head, m

8

-

Dimensions, mm

2100*1700*1100

-

Weight, kg

1400

-

Engine power, kW

200

-

Pump pressure, m

55...37

-

Power

Three-phase alternating current

-

Capacity, m3/h

250...1000

-

Temperature of pumped fluid, °С, not more than

90

-

Seal type

Sleeve

-

Revolution rate, rpm

1500-50

-

Electric power engine

ВА280S2 (ВА250М2)

The main feature of spiral casing (screw) pump assemblies is that screw wheels are used in them. The wheels have special screw blades with constant or variable pitch.

It gives us an inter-blade channel that enables low hydrodynamical load of blades and high anti-cavitation and power characteristics.

Spiral casing screw pumps are a pump option adapted from outer space engineering.